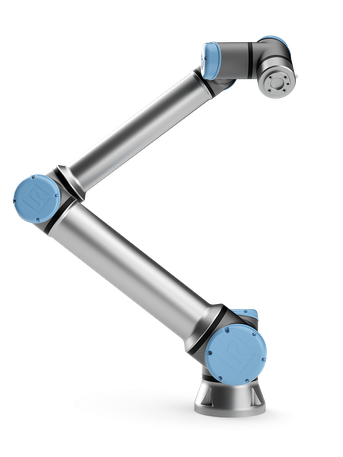

The UR10e is our medium duty industrial collaborative robot that combines both long reach and high payload. This cobot will seamlessly integrate into a wide range of applications and delivers endless automation possibilities.

UR10e

Medium-sized, versatile cobot

Your business, your way

Automating repetitive tasks has, from a technology standpoint, never been the challenge. The challenge has been finding the right tool that will enable you to adapt to the future of manufacturing.

Our most popular collaborative, industrial robot, the UR10e, is supporting customers globally in automating regular tasks such as palletizing, machine tending and welding. It also enables the development of unbelievably creative solutions, such as plastic picking in rivers, glass manufacturing, or car fueling solutions.

This cobot provides sufficient payload and reach capabilities, and is bundled with our powerful ecosystem of UR+ components and kits, making many tasks possible to automate. At the same time, the UR10e is re-deployable and fast to reprogram, giving you the flexibility to change set-up, when required.

Productivity

Increase uptime and productivity, while eliminating mistakes by introducing automated, standardized procedures.

Agile

Create new solutions, re-use programs for recurrent tasks and move the cobot to new processes if required.

Employee-support

Give your employees the freedom to focus on what they are best at and leave the rest to the cobot.

UR10e Applications

The UR10e can be used in a variety of applications. Click the most popular applications below to learn more.

True payload performance

Future-proof your facility with a cobot which enables you to grow with your tasks. When requiring to lift heavy objects over the maximum distance, do not limit yourself by the way your end-effector is mounted. If the objects require a change of how they are being lifted, resulting a shift in the center of gravity, the UR10e will support you in this change.

Lights out, work on

Automating tasks gives you the possibility to run tasks autonomously without constant monitoring of your employees. In addition, UR cobots use less electricity than traditional industrial robots. While the UR5e can lift 5 kg (11 lbs), it only consumes an average of 200 Watt, the same as a gaming console. You can power up your work processes, while keeping electricity consumption low.

Unlock the full potential of your cobot fleet

By integrating your robots with our comprehensive connectivity platform, you’ll benefit from enhanced productivity, minimized downtime, and efficient fleet management – all from the convenience of your office, wherever that might be.

Designed to improve your work

While our goal is to make automation available for anyone, anywhere, we also aim to support your journey in revolutionizing your business by enabling safe and collaborative human-robot interaction.

Fast deployment

The out-of-box experience for an untrained operator to unpack the cobot, mount it, and program the first simple task is typically less than an hour.

Space saving

Our cobot's small footprint opens opportunities to automate tasks in existing manufacturing setups where floorspace is often set and at a premium.

Power consumption

Automating tasks gives you the possibility to run tasks autonomously without constant monitoring of your employees. In addition, UR cobots use less electricity than traditional industrial robots.

Collaborative and safe

All UR cobots come with built-in safety features, including force-sensing technology and collision detection. These features allow our cobots to work alongside you without the need for safety barriers or cages, increasing productivity and promoting a safe working environment.

Motion control

Smooth movements are key for process applications such as dispensing, welding and machine loading or others. With a high focus on increased life-time and quality, our motion control algorithms enable less wear on the joints to increase uptime and decrease maintenance, while enabling the cobot to move at high speeds.

Get the most out of your cobot

UR Academy offers a series of step-by-step programming examples and tutorials for troubleshooting and repair tasks.

Tool Configuration

Learn how to set the tool center point (TCP), and how to adjust payload & center of gravity correctly.

Safety planes

Learn how to create and configure safety planes. A safety plane can prevent the robot from moving beyond it in normal mode, reduced mode or both; or it can trigger reduced mode.

Learn more

Visit UR Academy and browse our entire catalogue of popular topics and resources available to learn the essentials of programming a UR cobot.

Ensure maximum uptime

With UR Care Services, you can rest assured knowing that your uptime is our priority. Our commitment to excellence ensures maximum uptime through 24/7 support, remote connectivity, and onsite Field Service for prompt break/fix repairs.

Do you have questions?

We prepared a list of frequently asked questions about the UR10e which you can find on our FAQ page.

UR Developer Suite

Looking to build a solution? We have consolidated all of our amazing content into a new space called the UR Developer Suite! Click here to find all the tools, tutorials and resources you need to succeed.

myUR Customer portal

Register your cobot today to access our customer portal: myUR. Download the latest software, submit a support ticket for virtual or on-site support, and review cobot data all in one place.

UR+ Ecosystem

Browse over 300 accessories ranging from glue dispensers to inspection cameras.

Request a quote

Complete the form to the right and we will get in touch with you.

The process is simple:

Complete the form.

A UR team member in your region will reach out to you to discuss your needs in more detail. An in-person, no-cost demo can also be arranged.

We will deliver a solution and quote that best suits your business needs.

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI